01509 816064

sales@central-conveyors.co.uk

Durable and efficient Baling Systems from Central Conveyors Ltd

bespoke design, fabrication and installation for over 30 years

bespoke design, fabrication and installation for over 30 years

Our high quality baler machines are able to compress large volumes of cardboard and can have several benefits including saving your company time, space, money and helping to increase your recycling output.

Effective management of waste disposal Reduce waste collection costs Creation of new revenue streams by selling compacted recyclable materials Reduce landfill tax costs Keep your business neat and tidy and hazard free

Waste Balers are used for compacting waste, including materials such as cardboard’s, plastics, papers and everything in-between. Balers can convert waste into solid blocks of recyclable materials. The benefit of this being it can be easily collected for recycling. Balers minimize the working space needed for waste storage and reduce the cost of waste collection.

A fully automatic baler is the ultimate baling option for those looking to produce significant bales of cardboard, plastic and other materials. Ideal for distribution or back hauling, fully automatic balers are easy to use and super-efficient money generating pieces of equipment.

Horizontal Balers are ideal for handling very large volumes of recyclable waste. Incorporating the latest state of the art technology, they can process a wide range of materials including cardboard, paper and plastic bottles.

CCL offers two kinds of Horizontal Baler - Semi Automatic and Auto Tie. Both are available in various different sizes capable of processing huge volumes of waste into bales weighing up to 600kg.

Waste balers and waste compactors greatly reduce the space occupied by your business’s waste by compressing it down into small, manageable bales. Baled cardboard, for example, occupies 90% less space, and containers such as cans and bottles can be reduced in volume by up to 95%! This not only makes your workplace cleaner and more environmentally friendly, but also means that your recycling waste will need to be removed less frequently, allowing you to make savings on manual labour and collection costs. Certain collectors will even offer a rebate on recycled materials.

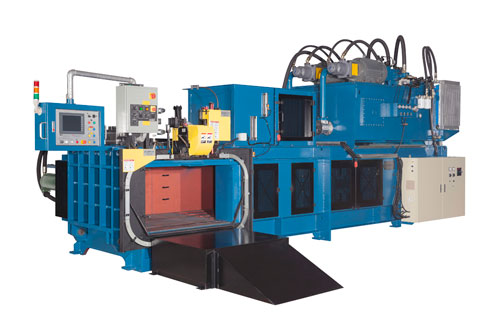

TWIN RAM BALERS

Twin ram balers are typically used in waste transfer stations or as part of a larger recycling MRF system where high volumes of various waste materials including RDF, SRF, plastic, PET and cardboard are being processed. High throughputs up to 40 tonne/hr are achievable. Waste can be fed into the machines using conveyor, shovel feed or selector grab.

A range of tying options is available. The fully automatic machines produce high density mill size bales, with bale weights of up to 1.4 tonnes. Two ram automatic balers can streamline bale production and dramatically increase profitability.